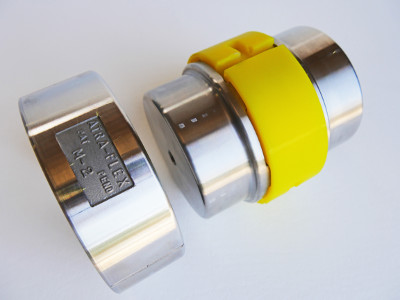

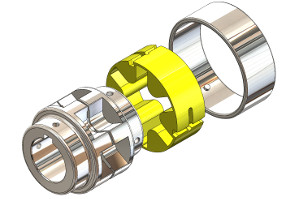

ATRA-FLEX® Millennium®

- Detect and Lock-On Ring Feature

- “Internal Support” of Insert for Higher Horse Power

- Higher Horse Power in a Smaller Package

- Large Bore Capacity

- No Exposed Shaft on Spacer Coupling

- Very Economical

- Torque Ratings up to 3,610,000lbs

Uniquely combines the stability of a compression type coupling with the safety of a shear coupling. In the event of a lockup, the insert will shear, minimizing the possibility of damaging your rotational equipment. No lubrication or routine maintenance is required. The rugged polyurethane insert is the only spare part and can be replaced in minutes without having to move the equipment or the shaft hubs. Standard inserts have a temperature range from -60° to 250° Fahrenheit with high temperature inserts available up to 350°. The inserts are available in a range of hardness to meet most torsional stiffness and torque requirements, and offers very high resistance to chemicals and weather.

ATRA-Flex® Couplings are manufactured in the USA. Standard hubs and rings are machined from solid carbon steel rounds and tubing, maintaining tight tolerances which provides excellent coupling balance. Stainless steels in grades 303,304 and 316 are also available for corrosive environments and food applications. We also offer a low cost alternative to stainless steel called Ferritic Nitro carburization. This process gives our carbon steel a uniform case hardening up to RC 62 and significantly prevents wear and corrosion. Inserts are made from durable custom compounded polyurethane that offer resistance to almost every fluid found in industry today.

ATRA-FLEX® offers all these advantages

- Change out of coupling insert is faster than any other

- Custom Compounded polyurethane inserts provide elasticity and resistance to high torque, shear and shock loads

- Unlike others, a single ATRA-FLEX coupling can be purchased to fit two different shaft sizes

- Elastic insert is highly resistant to humidity, oils, corrosion and chemicals; retains performance characteristics at temperatures from 60℉ to 250℉

- No lubrication or service is required

- 70,000 hours or more with no signs of wear

- May be installed horizontally or vertically; can rotate in either direction.

- No metal to metal contact between coupling parts

- Initial cost is low and maintenance and downtime are minimal.

- High temperature inserts (RED) available to 350℉