QUALITY, USA MANUFACTURED FLEXIBLE COUPLINGS

Large Enough to Handle Your Toughest Applications, Small Enough to Care

Here at ATR Sales Inc. We are committed to excellence. We pride ourselves in producing a quality USA Made product and services that will add value to your operation. We take the time to make sure you are sized up correctly on standard coupling orders and make sure the customers’ needs are met when requesting custom designed couplings. We pride ourselves in being a manufacture that treats every customer as a priority and have a reputation for getting into production and delivery time that outshines the competition.

ATRA-FLEX Can Replace virtually all styles of couplings in high- and low-torque applications for plant standardization.

Benefits:

- Torque Ratings up to 3,610,000 (lb-in)

- Shaft Capacities up to 20.000

- Suitable for horizontal and vertical applications, reversing and stop-start applications

- No lubrication needed

- ATRA-FLEX couplings are machined from solid steel which provides excellent inherent balance / we offer dynamical balancing for high speed operation

- Stainless Steel available in all styles

- PATENTED MELONITETM Process available as cost alternative to stainless steel provides excellent corrosion resistance

- Spacer Couplings, Drop Out Spacers, limited End Float, Floating shafts, Flywheel, Brake wheel and Axial Slide

- Available with Browning Bushings , QD Bushings , Tape-Lock systems

- Snap ring, floater rings and bolt on rings available

- Our quality polyurethane Inserts are formulated to outlast the competition. The inserts are available in a range of hardness to meet most torsional stiffness and torque requirements as well as offering very high resistance to chemicals and weather. Some have been known to run up to 70,000 hours. Inserts available to accommodate high torque, high dampening and high heat up to 350℉

Applications:

- Motor to gearbox. (Low torque/high speed)

- Gearbox to driven equipment. (High torque/low speed)

- Motors to pumps.

- Any drive shaft to a driven shaft.

- ATRA-FLEX® Reduces Downtime: ATRA-FLEX provides a solution to one of the most persistent and troublesome problems facing maintenance personnel-periodic coupling failure and the expense to go with it. Reduce Maintenance and downtime with the ease of installation and replacing inserts. If a new insert is needed, a low-cost replacement insert can be installed in minutes without moving either the prime mover or the driven equipment. When inserts shear there is no metal to metal contact. No need to replace hubs. No need to move equipment. Simply replace inserts within minutes and be back in motion.

- ATRA-FLEX Handles Misalignment: couplings will handle Radial/ Parallel, Angular, and Axial misalignment up to 2 degrees.

- ATRA-FLEX is a Top Choice for Standardization: ATRA-FLEX can replace virtually all styles of couplings reduce time and maintenance by eliminating messy grid and gear style couplings. ATRA-FLEX couplings are available in high- and low-torque applications for plant standardization. The only spare part required are your spare polyurethane inserts, saving you stocking space and money.

Millennium®

A Series®

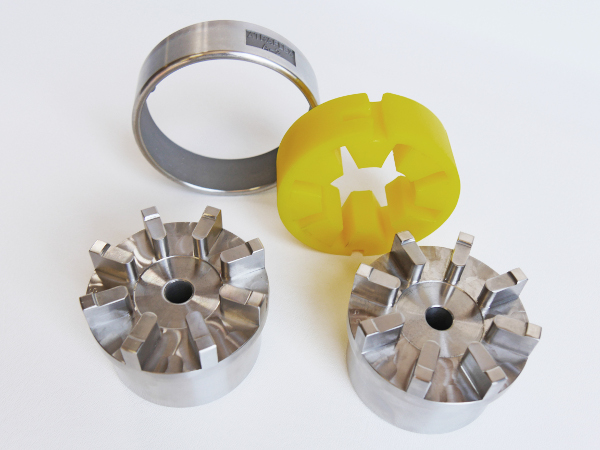

ATRA- FLEX Millennium® and A series® There are only four parts in these two coupling series. The two identical hubs made of steel, each with four, six or eight teeth, depending on load and size. The split insert, which is made of specially compounded polyurethane, fits between the hubs. The outer steel holding ring has no nuts or bolts.

ADVANTAGES

- Change out of coupling insert is faster than any other.

- Custom compounded polyurethane inserts provide elasticity and resistance to high torque, shear and shock loads.

- Unlike others, a single ATRA-FLEX coupling can be purchased to fit two different shaft sizes.

- Elastic insert is highly resistant to humidity, oils, corrosion and chemicals; retains performance characteristics at temperatures from -60 degrees F to +250 degrees F

- No lubrication or service is required.

- ATRA-FLEX couplings may be installed horizontally or vertically; can rotate in either direction.

- Operation is completely silent at all speeds and loads.

- No metal-to-metal contact between coupling parts.

- Initial cost is low, and maintenance and downtime are minimal.

- High temperature insert (red) available up to +350 degrees F

ATRA-FLEX® Innovated Others Followed

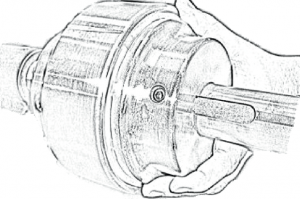

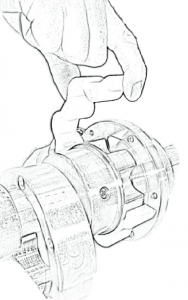

After hubs and holding ring are installed on shafts, the teeth are then aligned parallel to each other, but not touching. Once installed, the hubs never need to be moved again. The elastic insert can then be installed in the slots formed by the parallel teeth. When the insert is in position, slide holding ring onto the polyurethane insert starting, centrifugal force will expand the elastic insert to fix it tightly to the inside of the steel ring.

After hubs and holding ring are installed on shafts, the teeth are then aligned parallel to each other, but not touching. Once installed, the hubs never need to be moved again. The elastic insert can then be installed in the slots formed by the parallel teeth. When the insert is in position, slide holding ring onto the polyurethane insert starting, centrifugal force will expand the elastic insert to fix it tightly to the inside of the steel ring.

T Flex® Patent # 7.244,186

Customers Rely on ATRA-FLEX® T-Series for Their Most Demanding Applications

Patented T-Flex® absorbs extreme torsional shock and vibration while accommodating angular, parallel, and axial misalignment without generating reactionary loads, which significantly increases bearing life.

Application Range: Coupling sizes available to transmit torque loads from 60 in/lbs. to over 3.24 million in/lbs. with shaft capacities ranging from .375 to over 20.00 running from low rpm to over 18,000 rpm.

Coupling Types: Close coupled, Spacer types, Limited End Float, Slide, Floating Shaft, Flywheel, Brake Wheel, Brake Disc, and made to order engineered couplings.

T Flex® Advantages

- T-Flex® uniquely combines the stability of a compression type coupling with the safety of a shear coupling. In the event of a lockup, the insert will shear, minimizing the possibility of damaging your rotational equipment.

- No lubrication or routine maintenance is required.

- The rugged polyurethane insert is the only spare part and can be replaced in minutes without having to move the equipment or the shaft hubs.

- Standard inserts have a temperature range from -60° to 250° Fahrenheit with high temperature inserts available up to 350°.

- The inserts are available in a range of hardness to meet most torsional stiffness and torque requirements, and offers very high resistance to chemicals and weather.

- T-Flex® couplings are suitable for blind assembly, horizontal or vertical, reversing, and stop/start applications.

- The Compact size to torque ratio with generous bore capacity allows proper sizing.

- Hubs are available for use with tapered bushings, lock assemblies, shrink discs, finished bored and keyed, taper bored, and spline bored.

Save Money and Downtime with easy Assembly and Disassembly:

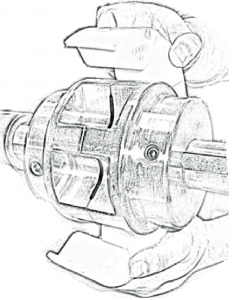

How it works: T-Flex close coupled couplings consist of four parts, the Ring Hub, Flex Hub, Insert, and Drive Ring. The Ring Hub and Flex Hub are installed on the shafts with the Drive Ring fitting over the Flex Hub. After coupling alignment, the Insert is placed around the Flex Hub engaging the bottom lobes of the Insert. The Drive Ring is then fitted over the Insert engaging the top lobes of the Insert. The Drive Ring is then fastened to the Ring Hub using high strength alloy steel socket head cap screws with high collar lock washers. The coupling will now transmit torque with silent, smooth reliable, maintenance free operation. Manufacturing: T-Flex is manufactured in the USA. Standard hubs and rings are machined from solid carbon steel rounds and tubing, maintaining tight tolerances which provides excellent coupling balance. Stainless steels in grades 303, 304, and 316 are also available for corrosive environments and food applications. We also offer a low cost, FDA approved alternative to stainless steel called Melonite Process which turns carbon steel a matte black and prevents wear and corrosion. TFlex® inserts are made from durable custom compounded polyurethane that offer resistance to almost every fluid found in industry today. Using TFlex® ensures dependable, maintenance free torque transmission for your rotational equipment, and comes with product / technical support from our knowledgeable staff with over 25 years’ experience.